Management

Successful establishment and maintenance of productive switchgrass stands require significant management by the producer/landowner. Further, the end goal for the stand (i.e., whether it will be for biomass, forage, or wildlife habitat) can dictate the management and inputs required. In this section, the management recommendations for switchgrass production will be presented.

On this page:

Variety Selection

One very important aspect of switchgrass that should be understood when selecting a variety is that there are two distinct categories (i.e., ecotypes): lowland and uplands. Lowlands are tall, coarse plants with exceptionally superior yield potential (30-50% higher than uplands in the southern USA). The lowlands are native to areas that had higher rainfall and mild winter temperatures (i.e., a climate that is more like Georgia). As a result, only lowland varieties are recommended for new switchgrass plantings in Georgia.

In contrast to the lowland varieties, uplands are shorter in stature and have lower yield potential. Uplands are generally more common to drier, colder areas of North America (e.g., the Northeast, Upper Midwest, and Upper Great Plains of the US). No natural crossing occurs across these ecotype categories, therefore upland and lowland types are reproductively distinct.

Currently, there are four lowland varieties that are recommended for use in Georgia: ‘EG 1102’ and ‘Kanlow’ (Piedmont and Mountain regions) and ‘EG 1101’ and ‘Alamo’ (lower Piedmont and Coastal Plain regions). The ‘Alamo’ and ‘Kanlow’ varieties were isolated from collections of plants found in the wild. Dr. Joe Bouton, now Emeritus Professor of Plant Breeding at the University of Georgia, bred and developed ‘EG 1101’ and ‘EG 1102’ from these initial collections. Both ‘EG 1101’ and ‘EG 1102’ have demonstrated substantial increases in yield potential over the ‘Alamo’ and ‘Kanlow’ varieties. In general, mature stands of these varieties should produce 5 – 7 tons per acre each year. Commercial seed production has begun on these and seed may be commercially available from CERES, Inc. New lowland switchgrass varieties are currently being developed at the University of Georgia and other institutions in the South. Changes and additions to the list of recommended switchgrass varieties will also be posted on the UGA switchgrass website.

Planting Recommendations

Switchgrass has a reputation for being difficult to establish. However, if proper and timely planting procedures are performed, switchgrass can become well-established in a minimal amount of time.

Switchgrass seedlings are not vigorous, and their productivity during the initial year is very poor. The reason for this is not readily apparent, but could partially be due to the very hot and dry summers we often have in Georgia. Recent experiments continue to show a need for using a pre-plant and post-plant herbicide program (see the Weed Control section), especially when using no-till methods, to give more productive stands. Management research is being performed at the University of Georgia and other institutions that will, in time, result in improved establishment practices.

As a consequence of poor seedling vigor, many producers have failed (or at least thought they had failed) on their first attempts to establish switchgrass. There are many potential causes of switchgrass establishment failures including planting too late, inadequate moisture at planting, incorrect planting depth, poor weed control, and excessive seed dormancy. In addition, some do not realize that a successful stand of switchgrass will look quite thin during establishment (especially relative to other grasses such as annual ryegrass, tall fescue, bermudagrass, etc.). Consequently, a successful establishment may be destroyed on the assumption that it was a failure.

Timing

Switchgrass should not be planted until the soil temperature is consistently above 65º F. Therefore, switchgrass should be planted in late April – early May. Seeding too early will result in the loss of some seed due to decay and herbivory and increases the competition from early-germinating weeds. Seeding after mid-May increases the risk of drought damage to the new stand. Late summer (August – September) seedings have been tried with some success, but we are still assessing the reliability of that method and do not recommend it at this time. Regardless of the timing of planting, ensure that sufficient soil moisture is present at the time of seeding to get the crop started.

Planting Method

Switchgrass can be planted using a no-till drill or drilled into a well-prepared seedbed with a conventional drill. Switchgrass is best established by creating a tilled, firm seedbed and using a cultipacker to firm the soil around the broadcasted or drilled seed. Unlike some NWS grasses that have "fluffy" appendages on the seed, switchgrass is smooth seeded and can be planted with most modern drills. The no-till establishment method is the most common method because it is more cost effective and reduces the potential for erosion at the establishment site.

A planting depth of ¼ to ½ inch is recommended. It is vital to not plant switchgrass seeds any deeper than ½ inch. The seeding rate for switchgrass is 5-6 lbs of pure live seed (PLS) per acre for forage and biomass crops. When planting for wildlife, reduce the seeding rate by 50-60% (i.e., 2 - 3 lbs PLS per acre). It is very important to adjust the seeding rate for PLS for each new seed lot that is used, since PLS varies from one seed lot to another. Information needed to correct for PLS is found on the seed tag. View more information on calculating PLS.

Weed Control

Switchgrass often takes several months to become well-established, and full establishment may take as much as two years. Weed control during this time is essential. Unfortunately, very few herbicides are currently available for the control of weeds when establishing switchgrass. Therefore, sites with heavy weed infestations should be avoided.

Site selection and preparation can aid weed control. Avoid fields that have competing perennial grasses like Johnsongrass and bermudagrass. These grasses should be well-controlled before site preparation begins.

Conventionally prepared seedbeds have generally resulted in better switchgrass stands in Georgia. To prepare the site, destroy the existing vegetation by spraying with the non-selective herbicide glyphosate (e.g., Roundup, Gly-4 Plus, etc.), then plow, disc, and pack the seedbed at least 1 month prior to planting. Then, after the weeds have germinated and emerged, apply a second application of glyphosate within 4 days of planting.

When no-till establishment methods are to be used, spray the area with glyphosate (e.g., Roundup, Gly-4 Plus, etc.) at least 6 - 8 wks in advance of planting* and then again within 4 days of planting. Preliminary research and on-farm experience indicate that no-till plantings of switchgrass generally suffer less weed pressure than when switchgrass is planted into conventionally prepared seedbeds. However, this is not always the case.

Mowing is usually necessary during the establishment year. Mow the stand to a cutting height of 6 – 8 inches when weeds reach a height of 18 – 24 inches. This will reduce weed competition and improve stand establishment. The mowing may need to be repeated later in the establishment year. However, do not mow after the first of September to enable the stand to develop sufficient root reserves before overwintering.

Several herbicides are being evaluated for use during the establishment phase, however, few herbicides are currently labeled for widespread use. Many broadleaf weeds can be controlled using 2,4-D amine or metsulfuron (e.g., Cimarron) once switchgrass reaches the four-leaf stage. However, competition with other grasses is often much more severe during the establishment year than the competition from broadleaf weeds. No nitrogen (N) should be applied during the establishment year to prevent competition from grassy weeds. In Tennessee, a Section-18 label for Accent (nicosulfuron) has been approved to control certain grassy weeds during establishment, and may be approved for use in other states. In non-cropland (i.e., wildlife habitat or non-grazed areas), Outrider (sulfosulfuron) can be used to control Johnsongrass and yellow nutsedge once switchgrass reaches the four-leaf stage. Once switchgrass becomes well-established, very little weed control is typically required. For more information on current weed control options, see the Georgia Pest Management Handbook or consult with your local County Extension Agent.

* If planting into a stand of tall fescue, the first application of glyphosate should be applied in the autumn prior to a spring establishment.

Fertilization

Biomass/Bioenergy Production

Switchgrass that is harvested for biomass/bioenergy can result in many nutrients being removed from the soil. However, if the biomass is not harvested until the plant has gone completely dormant (late November or later in the fall or winter), many of the nutrients within the plant will have been remobilized and transported to the roots for overwintering.

As a result, soil testing should be done every 3-5 years to ensure that the soil is maintained at a pH of 5.5 and does not fall below adequate levels of phosphorus (P2O5 > 10 ppm or 20 lb/A), potassium (K2O > 90 ppm or 180 lb/A), and other nutrients. More information on the fertilization rates that will be required to meet specific soil fertility goals can be found on UGA's Agricultural and Environmental Services Laboratories' website and in their "UGFertex" database.

Stands of switchgrass grown as a biomass/bioenergy crop should receive 50 to 75 lbs of nitrogen (N) per acre each year. This should be applied within two weeks of spring green-up. The nitrogen requirement of switchgrass for biomass may be at least partly met through the use of N-fixing, winter annual legumes.

Forage Production

Switchgrass that is harvested as hay will result in many nutrients being removed from the soil. Thus, adequate soil fertility needs to be maintained to avoid yield loss. Soils in switchgrass hay fields should be maintained at a pH of 5.5 or greater and with medium soil test P and K values. These stands should receive 40 - 60 lbs of N per acre at green-up. If soil moisture is adequate and additional forage is desired, additional applications of up to 60 lbs of N per acre should be applied after each subsequent hay harvest (except after the last cutting of the season).

Switchgrass can be grazed if the manager carefully prevents grazing below heights of 8 inches. This will require some level of grazing management and rotation. The N rate on grazed switchgrass pastures should be 30 - 40 lbs at green-up and after each subsequent grazing (if soil moisture is adequate).

Wildlife

Though it is not as high-yielding when soil fertility is low, switchgrass is very tolerant of low fertility. Even so, if switchgrass is grown for wildlife purposes, some soil amendments may be necessary to maintain the soil pH at 5.0 or greater and with medium-low soil test P and K values. Little, if any, additional N will be necessary.

Harvesting

Biomass/Bioenergy Production

For biomass production, switchgrass can be harvested as a one- or two-cut system. However, since there is not typically a total yield advantage for the two- cut system and the two-cut system results in more nutrient removal per acre, the one-cut system is likely to be the most economically advantageous system. In the one-cut system, the switchgrass is harvested once, several days (or weeks) after the first killing frost.

Regardless of system, switchgrass should be cut at least 6 inches high (preferably 8 inches). The taller stubble will help allow the tires on the harvest equipment to roll over the crop stubble and reduce the chances of punctured and damaged tires. This taller stubble height also has been shown to improve stand survival and vigor as the stand ages.

Currently,switchgrass biomass is harvested with conventional hay equipment (large round or rectangular balers). This is desirable because it utilizes existing equipment for producing, handling, storing, and transporting the biomass. It is worth noting, however, that baling switchgrass biomass with equipment from the hay enterprise results in additional maintenance, repairs, and down-time with this equipment.

Forage Production

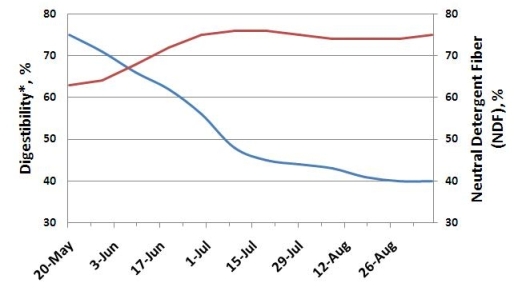

Switchgrass has very unique characteristics that make it useful as hay and pasture. First, it is among the earliest warm season grass to break winter dormancy with growth beginning in early March in South Georgia. This vegetative growth is also very high in nutritional quality (60-70% TDN and 10-12% crude protein), but quality can drop quickly once the forage begins to mature. Thus, grazing or hay cuttings should be performed at the boot stage of maturity to ensure an optimum balance between yield and quality. This generally will occur in early June.

The quality of switchgrass declines rapidly once the forage begins to mature. [*Digestibility was measured by in vitro dry matter digestibility (IVDDM). Lines represent a two-year average. Source: Mitchell, et al., 2001 Agron. J.]

It is critical to avoid making a first cutting that is too late. In addition to the rapid decline in forage quality, total forage yield may be impacted if the first cutting is delayed too late. Recent research throughout the Southeast has shown that just over half of the total seasonal yield of switchgrass will occur before late June. Therefore, the timing and method of forage harvests/grazings should be performed in a way that takes advantage of this growth distribution fact.

In addition to cutting the forage at the appropriate stage of growth, the forage must not be cut below an 8 inch cutting height. Cutting or grazing the forage at this level (or higher) will leave sufficient residual leaf area to allow for rapid regrowth. In addition, cutting below this 8 inch level risks damage to the growing point of the switchgrass plant.

CAUTION: There is some evidence to suggest that horses may exhibit an excessive hair loss and sensitivity to sunlight when consuming switchgrass hay. The causal agent remains undiscovered. Therefore, at this time, switchgrass is not recommended as hay for horses.

Maintenance of Switchgrass Stands for Wildlife

Switchgrass stands that are designated as wildlife habitat will require the manager to periodically maintain the stand. This is necessary to set back the encroachment of woody and undesirable species and to maintain an open structure at ground level. Periodic removal of the biomass by the previously described harvesting methods, burning, or mowing and discing can maintain the stand's ability to provide habitat to wildlife. However, this removal of biomass must be timed appropriately to ensure that wildlife are only minimally affected by this process. (Note: Burning or mowing and discing are not recommended within one year of establishment.)

Burning

A controlled fire can be used to destroy the residual biomass. However, this should be performed before spring green-up in late February (S. Georgia) - mid-March (N. Georgia). Removing the biomass at this time will have a minimal effect on grassland wildlife species (birds, rabbits, etc.). If woody shrubs or trees have begun to invade the area, the prescribed burn should take place just after bud break.

In addition to the control of the diversity of plant species, prescribed fires increase the availability of nutrients and can stimulate early spring green-up and faster growth. However, prescribed fires can be dangerous, especially for stands of switchgrass that have produced a lot of biomass (i.e., fuel for the fire).

It is critically important to follow proper prescribed burning procedures. A detailed resource for proper burning procedures is an article produced by Auburn University entitled "Use of Fire in Bermudagrass Management."

Though this publication was written for those burning-off bermudagrass hayfields, the principles and methods are very similar for stands of NWS grasses like switchgrass.

Outdoor burning bans (periodic or permanent) are in place in some areas. Therefore, it is critical to contact the state forestry commission to ensure compliance with these ordinances. The Georgia Forestry Commission’s (GFC) on-line burn permit system and 1-877-OK2-BURN phone system will inform whether or not burning is legal in a given county. Furthermore, each area's local GFC professional should also be able help advise you of the current burn ban status.

Mowing and Discing

If burning is not a viable option, similar results can be obtained by periodic mowing ("bushhogging") and discing of the stand. However, mowing should NOT be done without discing (or burning) because this residual litter will negatively impact the habitat for wildlife, reduce the stand, and tie-up nutrients. Discing can be done without first mowing the stand, but this may need to be done on a more regular basis (each year or every two years). Discing alone will also require additional trips across the field, especially if a highly-productive lowland variety of switchgrass is used.

Mowing and discing is often best done in blocks or strips. It is recommended to do 1/3 of the field each year. In this way, the whole area will have been subjected to maintenance over a 3 year period. Be sure that the areas are situated across the slope. This will avoid discing up and down the slope, which can increase the risk of soil erosion.

Additional Resources

Planting and Managing Switchgrass as a Dedicated Energy Crop - one of the most comprehensive management guides for switchgrass production.

This handbook includes some of the latest findings from current and ongoing research and includes region-specific recommendations. Though this management guide was commissioned by a private company, it was written by researchers from The Samuel Roberts Noble Foundation and South Dakota University and edited by other leading researchers in this field. Though it places an emphasis on Blade Energy Crop™ varieties, these are the same varieties that we recommend in Georgia.

Additional links to more information on the management of switchgrass can be found on the Related Links page.